Ensuring that power systems keep operating safely requires close collaboration between skilled professionals and advanced technologies. Ongoing inspection of poles, towers, lines, and other field assets is one of the most important utility functions — and historically, routine inspections have been very time- and labor-intensive, and costly.

For years, utilities have been using drones to increase the efficiency of routine inspections. Today, utilities can save even more money and time, while enhancing safety and asset management, with a more robust approach to virtual inspections.

In our latest webinar, an expert panel explores a more integrated approach to virtual inspections. In addition to employing even more advanced unmanned aircraft, virtual inspections can also utilize:

- Experienced pilots authorized to fly drones farther than is usually allowed

- Ultra-high-resolution cameras and sensors

- Software powered by artificial intelligence

- Experienced utility inspectors who review field data remotely

In advanced virtual inspections, drone payloads can include cameras with the ability to capture images at a much higher level of resolution than previously possible. Cameras and sensors also can capture video, infrared, UV, and other types of useful data. This can support 3D reconstructions and advanced analysis by human inspectors and specially trained artificial intelligence.

Advanced virtual inspections enable much greater efficiency, fewer truck rolls, lower costs, and faster results that support better decisions for asset management and O&M. This approach also enhances the safety of utility crews, utility assets, and the public.

Speakers:

- John Daniels, Chief Customer Officer, eSmart Systems

- Paul Petersen, GIS Manager, EDM International

- William Wheeler, Director of Operations, Phoenix Air Unmanned

- Lau Nørgaard, Chief Technology Officer, Phase One

Other Webinars You May Like

-

Webinars

WebinarsWatch our webinar – How AI & Virtual inspections changed operations at Xcel Energy

Inspecting transmission and distribution assets is tremendously time- and labor-intensive for utilities. Watch this webinar to learn the benefits and requirements of using a virtual inspection program and what AI is and isn’t capable of doing.May 12th 2023 -

Webinars

WebinarsWatch our webinar – Incorrect asset data – why it puts congestion management strategies at risk

Stedin, DSO for 2.3+ million customers in the Netherlands, realised that the asset data they used for their network calculations resulted in anomalies. Watch this webinar to understand Stedin’s approach to validating asset data for their 22,000 Medium Voltage substations.October 02nd 2023 -

Webinars

WebinarsWatch our webinar – How virtual inspections support capital projects

Watch our very engaging on-demand webinar with Xcel Energy on how AI plays a key role in the next generation of electrical infrastructure inspections.October 27th 2022 -

Webinars

WebinarsWatch our webinar – Master your substation asset data: Expert insights and strategies revealed

Watch this webinar to learn how to improve poor quality and incomplete data for your substations and how you can achieve lower costs and a much faster response to faulty assets by relying on accurate, up-to-date data.May 09th 2023 -

Webinars

WebinarsWatch our webinar – Virtual T&D line inspections – Are they practical, scalable and cost-effective?

Watch this session to:

– Learn what virtual inspections are.

– Discover how they fit into utilities’ current processes and how they can be scaled.

– Uncover virtual inspection pitfalls and benefits that can be achieved.April 20th 2022

Ensuring that power systems keep operating safely requires close collaboration between skilled professionals and advanced technologies. Ongoing inspection of poles, towers, lines, and other field assets is one of the most important utility functions — and historically, routine inspections have been very time- and labor-intensive, and costly.

For years, utilities have been using drones to increase the efficiency of routine inspections. Today, utilities can save even more money and time, while enhancing safety and asset management, with a more robust approach to virtual inspections.

In our latest webinar, an expert panel explores a more integrated approach to virtual inspections. In addition to employing even more advanced unmanned aircraft, virtual inspections can also utilize:

- Experienced pilots authorized to fly drones farther than is usually allowed

- Ultra-high-resolution cameras and sensors

- Software powered by artificial intelligence

- Experienced utility inspectors who review field data remotely

In advanced virtual inspections, drone payloads can include cameras with the ability to capture images at a much higher level of resolution than previously possible. Cameras and sensors also can capture video, infrared, UV, and other types of useful data. This can support 3D reconstructions and advanced analysis by human inspectors and specially trained artificial intelligence.

Advanced virtual inspections enable much greater efficiency, fewer truck rolls, lower costs, and faster results that support better decisions for asset management and O&M. This approach also enhances the safety of utility crews, utility assets, and the public.

Speakers:

- John Daniels, Chief Customer Officer, eSmart Systems

- Paul Petersen, GIS Manager, EDM International

- William Wheeler, Director of Operations, Phoenix Air Unmanned

- Lau Nørgaard, Chief Technology Officer, Phase One

Other Webinars You May Like

-

Webinars

WebinarsWatch our webinar – How AI & Virtual inspections changed operations at Xcel Energy

Inspecting transmission and distribution assets is tremendously time- and labor-intensive for utilities. Watch this webinar to learn the benefits and requirements of using a virtual inspection program and what AI is and isn’t capable of doing.May 12th 2023 -

Webinars

WebinarsWatch our webinar – Incorrect asset data – why it puts congestion management strategies at risk

Stedin, DSO for 2.3+ million customers in the Netherlands, realised that the asset data they used for their network calculations resulted in anomalies. Watch this webinar to understand Stedin’s approach to validating asset data for their 22,000 Medium Voltage substations.October 02nd 2023 -

Webinars

WebinarsWatch our webinar – How virtual inspections support capital projects

Watch our very engaging on-demand webinar with Xcel Energy on how AI plays a key role in the next generation of electrical infrastructure inspections.October 27th 2022 -

Webinars

WebinarsWatch our webinar – Master your substation asset data: Expert insights and strategies revealed

Watch this webinar to learn how to improve poor quality and incomplete data for your substations and how you can achieve lower costs and a much faster response to faulty assets by relying on accurate, up-to-date data.May 09th 2023 -

Webinars

WebinarsWatch our webinar – Virtual T&D line inspections – Are they practical, scalable and cost-effective?

Watch this session to:

– Learn what virtual inspections are.

– Discover how they fit into utilities’ current processes and how they can be scaled.

– Uncover virtual inspection pitfalls and benefits that can be achieved.April 20th 2022

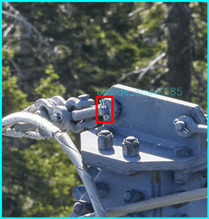

The project, completed in 2021, focused on hardware and defects identification. The project looked at cotter pins, with an emphasis on loose and upside-down cotter pins. The project was able to automatically detect over 11,000 total and successfully identify 781 upside-down pins within a few seconds. The project enabled the public utility’s maintenance engineers to efficiently locate the 2-inch upside-down cotter pins on up to 100 feet high towers and assess their conditions. The outcome of the project is an increase in powerline safety, field worker safety, and, as result, community safety. The case-study described below demonstrates the potential of virtual powerline inspections in enhancing community safety.

Introduction

Multiple large-scale wildfires are reported in the US every year. Such events cost tens of billions of dollars in direct costs such as property loss and damage and indirect costs such as long-term health exposures, market loss, and non-collectable taxes, etc[1]. The consequences of such events can be disastrous from a human, material, and environmental perspective.

Defects in the power grid can cause wildfires; active causes can include a tree or branch falling over a powerline and sparking a wildfire. Triggered material or old powerline components can generate arcs or sparks, and under dry weather conditions and with dry surrounding vegetation, can lead to disastrous and hard to control wildfires.

To minimize the risk of wildfires caused by power grid issues, it is important to ensure conductors do not encounter any foreign objects like trees, other conductors, or the ground. This can only be achieved by properly managing vegetation in areas surrounding powerlines and by sufficiently keeping conductors separate from each other. Spacers and cotter pins, specifically, play a critical role in keeping conductors separated. Spacers keep conductors away from each other, while cotter pins hold the parts in transmission towers in place.

Cotter pins, however, could wear out and loosen over time. A loose and upside-down cotter pin is more likely to slip, becoming unsafe and increasing the chance of conductor failure and the probability of generating an arc flash touching their surroundings. Therefore, a main focus of the efforts led by the public utility to minimize the chance of wildfires is the management and maintenance of cotter pins specifically. As they are more likely to be upside-down than loose, the public utility decided to first assess the number of upside-down cotter pins on their grid. However, manually identifying the orientation of cotter pins is a tedious and resource-consuming task, as there can be as many as 50 2-inch cotter pins on each lattice tower, and the grid in this case includes over 1000 lattice towers.

The new approach

Both the public utility and the engineering and construction company defined the inspection process based on the required scope and accessibility of each structure. eSmart Systems shared their expertise to support that process definition and provided access to Grid Vision, a virtual inspection solution for power grids, enabling professionals to inspect powerlines from the office. Virtual inspection is a new approach to conducting powerline inspections by leveraging the power of automation, smart algorithms, and user-friendly interfaces to facilitate the work of the professionals analyzing the status of the infrastructure. Virtual inspections are also supported with artificial intelligence (AI) to automatically and promptly identify all the components of a power grid, as well as to detect various failures in the grid. With the application of such technologies, the software was able to identify 781 instances of upside-down cotter pins out of 11,000 cotter pin crops, within seconds (Figure 1).

Figure 1: Examples of an upside-down cotter pin automatically detected in the grid.

By associating those findings with information of the tower on which the upside-down cotter pins were located, the public utility could identify which towers required attention instantly. This approach has improved the efficiency and accuracy of identifying upside-down cotter pins and improved safety by having line workers only climbing structures when needed.

The utility also looked at other types of key components and their failure modes (flashed insulators, woodpecker damage on wooden transmission towers, rust on lattice towers, etc.) that could be identified utilizing this new approach for a proactive maintenance of powerlines. C-hooks and shackles, which are used for affixing insulators to brackets attached to crossarms, are particularly important components to look at in this context. The lattice towers are over 50 years old. Nonetheless, the virtual detection system was able to identify over 25,000 crops of C-hooks and shackles on the images captured during the inspection and very little wear was detected.

Figure 2: Examples of (a) a c-hook in good condition, (b) very limited level of wear seen on c-hooks during the project and (c) a shackle, highlighting the general good condition of those components in the grid.

Utilities are constantly looking for innovative ways to improve safety inspection and grid maintenance. This project has demonstrated that well-designed solutions supported by AI are game-changing tools, making inspection easier, more efficient and safer. The collaborative AI approach was instrumental to ensuring the correct components were identified and defects detected. The construction company’s review of the results from eSmart Systems’ Grid Vision solution ensured that high quality inspection standards were met and illustrated how utilities and engineering companies can benefit from virtual inspection tools.

The success of this program demonstrates how proactive actions can be implemented to enhance power grid management efficiency, and proves that smart solutions could help prevent wildfires, in addition to illustrating numerous other advantages, such as new quality assessment possibilities, defect detection standardization, and increased trust in data.

Contact us today and see how Grid Vision is transforming the way the world’s leading energy providers inspect and maintain critical infrastructure.

[1]https://www.nfpa.org/News-and-Research/Publications-and-media/NFPA-Journal/2020/November-December-2020/Features/Wildfire

Zeina Othman from Mälardalens University in Sweden is working in partnership with eSmart Systems on her thesis “Re-designing Organizational Routines in the Echo of AI Algorithms”. The overall objective of this thesis is to develop an understanding of how organizations need to re-design and influence processes when introducing and deploying Artificial Intelligence (AI).

eSmart Systems has been working with AI within our Grid Vision® solution for over 10 years, as a co-pilot for conducting virtual inspection of transmission and distribution grids through a process we call Collaborative-AI. We are working with over 50 utilities globally in supporting their journey to virtual inspections using Grid Vision.

Technology has a huge impact on large organizations in terms of processes, adoption, and change management, and we are thrilled to partner with Zeina to explore this journey with one of our key European customers.

Stayed tuned to learn more about Zenia’s work by signing up to our newsletter here: GridVision.com/newsletter

About Zeina Othman

Zeina Othman studies and teaches international project management at Mälardalens University in Sweden. Prior to her Ph.D. studies, Zeina worked in project management with the UN and non-governmental organizations in Jordan including USAID and Jordan River Foundation. She also worked in Abu Dhabi/UAE for Accenture and Lockheed Martin Global Inc.

Come by our booth at E-world 2023 and witness the power of Grid Vision®

eSmart Systems is a leading provider of artificial intelligence (AI)-powered solutions for the inspection and maintenance of critical infrastructure. Our Grid Vision solution provides a data-driven and condition-based approach to infrastructure inspections and asset management.

Grid Vision is transforming the way the world’s leading energy providers inspect and maintain critical infrastructure.

Come by our booth #610 in hall 5 at E-world and explore how we are working with utilities globally to improve their inspections and asset data.

Come by our booth at E-world 2023 and witness the power of Grid Vision®

eSmart Systems is a leading provider of artificial intelligence (AI)-powered solutions for the inspection and maintenance of critical infrastructure. Our Grid Vision solution provides a data-driven and condition-based approach to infrastructure inspections and asset management.

Grid Vision is transforming the way the world’s leading energy providers inspect and maintain critical infrastructure.

Come by our booth #610 in hall 5 at E-world and explore how we are working with utilities globally to improve their inspections and asset data.

Ensuring that power systems keep operating safely requires close collaboration between skilled professionals and advanced technologies. Ongoing inspection of poles, towers, lines, and other field assets is one of the most important utility functions — and historically, routine inspections have been very time- and labor-intensive, and costly.

For years, utilities have been using drones to increase the efficiency of routine inspections. Today, utilities can save even more money and time, while enhancing safety and asset management, with a more robust approach to virtual inspections.

In our latest webinar, an expert panel explores a more integrated approach to virtual inspections. In addition to employing even more advanced unmanned aircraft, virtual inspections can also utilize:

- Experienced pilots authorized to fly drones farther than is usually allowed

- Ultra-high-resolution cameras and sensors

- Software powered by artificial intelligence

- Experienced utility inspectors who review field data remotely

In advanced virtual inspections, drone payloads can include cameras with the ability to capture images at a much higher level of resolution than previously possible. Cameras and sensors also can capture video, infrared, UV, and other types of useful data. This can support 3D reconstructions and advanced analysis by human inspectors and specially trained artificial intelligence.

Advanced virtual inspections enable much greater efficiency, fewer truck rolls, lower costs, and faster results that support better decisions for asset management and O&M. This approach also enhances the safety of utility crews, utility assets, and the public.

Speakers:

- John Daniels, Chief Customer Officer, eSmart Systems

- Paul Petersen, GIS Manager, EDM International

- William Wheeler, Director of Operations, Phoenix Air Unmanned

- Lau Nørgaard, Chief Technology Officer, Phase One

Ensuring that power systems keep operating safely requires close collaboration between skilled professionals and advanced technologies. Ongoing inspection of poles, towers, lines, and other field assets is one of the most important utility functions — and historically, routine inspections have been very time- and labor-intensive, and costly.

For years, utilities have been using drones to increase the efficiency of routine inspections. Today, utilities can save even more money and time, while enhancing safety and asset management, with a more robust approach to virtual inspections.

In our latest webinar, an expert panel explores a more integrated approach to virtual inspections. In addition to employing even more advanced unmanned aircraft, virtual inspections can also utilize:

- Experienced pilots authorized to fly drones farther than is usually allowed

- Ultra-high-resolution cameras and sensors

- Software powered by artificial intelligence

- Experienced utility inspectors who review field data remotely

In advanced virtual inspections, drone payloads can include cameras with the ability to capture images at a much higher level of resolution than previously possible. Cameras and sensors also can capture video, infrared, UV, and other types of useful data. This can support 3D reconstructions and advanced analysis by human inspectors and specially trained artificial intelligence.

Advanced virtual inspections enable much greater efficiency, fewer truck rolls, lower costs, and faster results that support better decisions for asset management and O&M. This approach also enhances the safety of utility crews, utility assets, and the public.

Speakers:

- John Daniels, Chief Customer Officer, eSmart Systems

- Paul Petersen, GIS Manager, EDM International

- William Wheeler, Director of Operations, Phoenix Air Unmanned

- Lau Nørgaard, Chief Technology Officer, Phase One

Other Webinars You May Like

-

Webinars

WebinarsWatch our webinar – How AI & Virtual inspections changed operations at Xcel Energy

Inspecting transmission and distribution assets is tremendously time- and labor-intensive for utilities. Watch this webinar to learn the benefits and requirements of using a virtual inspection program and what AI is and isn’t capable of doing.May 12th 2023 -

Webinars

WebinarsWatch our webinar – Incorrect asset data – why it puts congestion management strategies at risk

Stedin, DSO for 2.3+ million customers in the Netherlands, realised that the asset data they used for their network calculations resulted in anomalies. Watch this webinar to understand Stedin’s approach to validating asset data for their 22,000 Medium Voltage substations.October 02nd 2023 -

Webinars

WebinarsWatch our webinar – How virtual inspections support capital projects

Watch our very engaging on-demand webinar with Xcel Energy on how AI plays a key role in the next generation of electrical infrastructure inspections.October 27th 2022 -

Webinars

WebinarsWatch our webinar – Master your substation asset data: Expert insights and strategies revealed

Watch this webinar to learn how to improve poor quality and incomplete data for your substations and how you can achieve lower costs and a much faster response to faulty assets by relying on accurate, up-to-date data.May 09th 2023 -

Webinars

WebinarsWatch our webinar – Virtual T&D line inspections – Are they practical, scalable and cost-effective?

Watch this session to:

– Learn what virtual inspections are.

– Discover how they fit into utilities’ current processes and how they can be scaled.

– Uncover virtual inspection pitfalls and benefits that can be achieved.April 20th 2022

Utility companies are required to inspect their grid on a regular maintenance cycle. Traditionally this work would be done by walking along, or flying helicopters over the power grid. Inspection and maintenance of power lines used to be tremendous and tedious work, not to mention extremely dangerous.

Even though most utility companies have moved over to image-based inspection, they have trouble sorting through the vast amounts of images. It is estimated that one expert can sort through 50 000 images per year.

Thanks to a Norwegian tech company, eSmart Systems, based in Halden, Norway, this tedious job can now be done faster, more accurate, more cost effective and a lot safer.

Images are imported into their software, Grid Vision, which uses collaborative artificial intelligence (AI) to detect faults in components. eSmart Systems estimate their solution can help utilities companies save inspection costs by 40 per cent.

In stress tests, eSmart Systems have been able to process 180 000 images an hour, more than three times the amount of what a human is capable of processing in a whole year!

Our solutions help utilities thrive in an evolving landscape and optimize infrastructure inspections to reach better decisions quicker and at a lower cost.

More precise defect detection

Åsberg ensures that Grid Vision is not created to make the detection experts redundant. The approach used in Grid Vision is Collaborative-AI, where the expert’s feedback on the recommendations made by the AI to raise the quality of their work, and free up time, that they can use to improve their service to their customers.

– As the experts work with the AI, it learns, gets smarter and even more precise. With faster image processing, the utilities can detect defects earlier and resolve any issues before they become a problem. The experts can even move their attention to predictive maintenance, says Åsberg.

eSmart Systems has one of the largest qualified data sets in the world. They have expanded their suite of solutions to create synthetic images. In graphic engines like Unreal, they create 3D models of digital components and add faults to give the AI more data to learn from.

– The utilities get more objective inspections and a better foundation to plan their maintenance budgets. Deeper insight and better documentation in the infrastructure can really make a difference ahead of the wildfire season for example, says Åsberg.

Industrial scale through the cloud

eSmart Systems currently serve utility companies across Europe and North America and have helped inspect more than 100 000 kilometers of transmission and distribution overhead lines and analyzed more than 3 million images. All because their solutions are built with the purpose of being scalable in Microsoft’s cloud platform, Azure.

eSmart Systems is a certified independent software vendor (ISV) partner with Microsoft. The entire solution is hosted in Azure.

– Our solution was born in Azure. We have never owned a server on our own. On a technical level, Microsoft and Azure has been totally crucial for our ability to scale, Åsberg explains.

The partnership has been fruitful on a commercial level as well.

– All our leads are generated through Microsoft’s ecosystem. It can be difficult for a small company from Norway to get the contracts with enormous utility companies on our own. The path to a meeting is much shorter when it is a technology giant like Microsoft that makes the call, says Åsberg.

Industry lead for power and utilities in Microsoft Norway, Tor Inge Åsen, underlines that the partnership is mutually beneficial.

– While we can supplement eSmart Systems thanks to our brand, they validate us in an industry where we have no solutions that are directly applicable as well. They give us a way into a vertical we would’ve struggled to get a foothold in without a partner with expertise in the field, Åsen confirms.

A solution for the future

The energy grid is the largest asset in the world, and a necessity if our society is to have any chance of making the green shift into a more electrified world.

– Our software will play a huge part in how utilities will prioritize investments. Maybe they can even defer infrastructure investments and focus on high-risk assets only, because they will be in more control over the maintenance needs. This gives eSmart Systems a higher purpose, and makes our job more meaningful, says Åsberg.

Contact us today and see how Grid Vision is transforming the way the world’s leading energy providers inspect and maintain critical infrastructure.

Norwegian company eSmart Systems was among one of the first in the world to develop an Artificial Intelligence based solution, Grid Vision®, for the inspection and maintenance of critical energy infrastructure. With over 20 years of experience, it has become the leading international player within its field. The company has global customers including several of the world’s largest energy companies, such as Naturgy, Xcel Energy and E.ON.

Oslo, Norway, August 22, 2022 – In the recently completed Series B share issue, the current investors – Equinor Ventures, Kongsberg Group, Nysnø Climate Investments, Energy Impact Partners, and Future Energy Ventures – together with the U.S.-based investment fund manager, Arosa Capital, have raised ~€40 million.

The capital will be used to accelerate the company’s commercial development and international growth.

Our investors’ deep domain expertise and strategic support will have a major impact on our commercial development,” said Henrik Bache, who became CEO of eSmart Systems last fall. “Our existing investors’ decision to continue to support us is an important vote of confidence – in both our company and our mission to create intelligent solutions that accelerate the energy transition to a sustainable future.

Arosa Capital, which manages traditional and alternative energy investments, and who recently became an investor of eSmart Systems, believes the company can take a leading position in the global energy market.

eSmart Systems has the right solutions, team, and investor base to succeed globally, and we believe it will play a vital role in the energy transition. We look forward to actively contributing to the growth trajectory that the company is on

Mr. Bache added: “We are thrilled that a respected, long-term strategic investor like Arosa Capital shares our view of growth opportunities going forward. The completion of this share issue in today’s financial climate is a confirmation of our company’s strong position and prospects.”

According to Princeton Environmental Research and Rystad Energy the global energy transmission network is expected to triple in size, and over $18 trillion is to be invested by 2050 to reach net zero, creating massive growth opportunities for eSmart Systems.

“The current geopolitical situation has increased attention on energy security and emphasized the need for a stable power grid. We are also experiencing more frequent occurrences of extreme weather, resulting from climate change, making power infrastructure more vulnerable. eSmart Systems is uniquely positioned to assist grid operators in meeting these challenges.”, says Mr. Bache.

Last summer, eSmart Systems acquired the Stavanger-based company Verico to strengthen and expand its international platform. Verico offers specialized product and services within Enterprise Asset Management complementing eSmart Systems’ existing services. The combined company employ 110 employees in Norway, Sweden, Germany, the Netherlands, the UK and the US.

Investment banks DNB Markets and Arctic Securities were financial advisors of the share issue.

About eSmart Systems

eSmart Systems is a leading provider of AI-powered solutions for the inspection and maintenance of critical infrastructure. With the Grid Vision® portfolio, the company provides Inspection Management and Asset Information Management solutions and services to utilities globally. Grid Vision provides a data-driven and condition-based approach to infrastructure inspections and support utilities to reduce inspection costs, improve inspection safety, improve the quality of asset data and prolong asset life. More information about the company can be found at www.esmartsystems.com.

About Arosa Capital

Arosa Capital Management LP is an U.S.-based alternative investment fund manager that focuses on energy both within traditional and alternative energy sources. Arosa was founded in 2013 and combines fundamental analysis with a long experience and deep knowledge of the energy markets to invest in venture companies, private and public companies, as well as in credit and commodities. More information about Arosa Capital can be found at www.arosacapital.com.